PCB Assembly often abbreviated as PCBA, refers to the process of populating a printed circuit board (PCB) with electronic components, transforming a bare circuit board into a fully functional electronic assembly. This critical step in electronics manufacturing involves various techniques for mounting components and ensuring the electrical integrity of a circuit, ultimately allowing the assembled board to perform its intended functions.

Key Aspects of PCB Assembly

1. Component Placement:

Surface Mount Technology (SMT): This method involves placing components directly onto the surface of the PCB. SMT components are usually smaller, allowing for higher component density and better performance at higher frequencies.

Through-Hole Technology (THT): With this method, components have leads that are inserted through holes in the PCB and soldered on the opposite side. This technique is typically used for larger components or those requiring extra mechanical support.

2. Soldering Techniques:

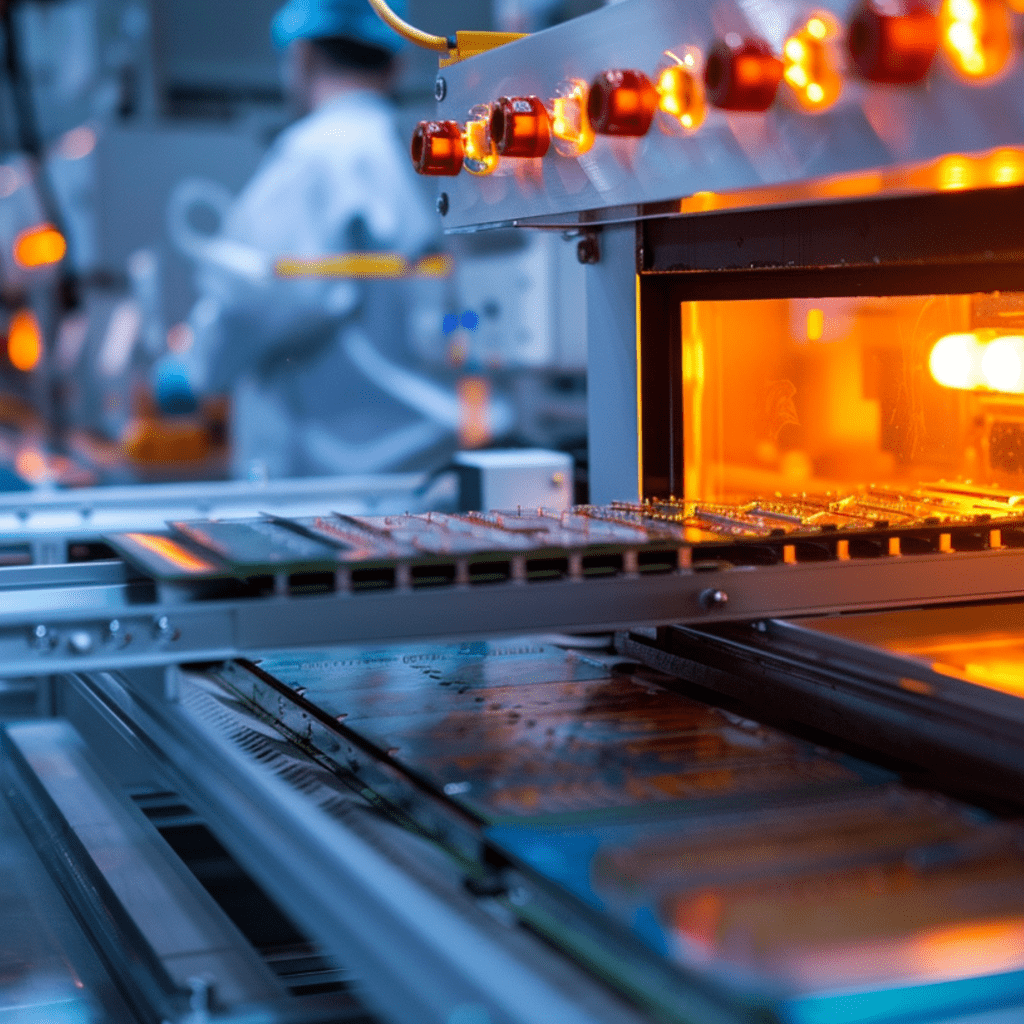

- Reflow Soldering: Commonly used for SMT components, reflow soldering involves applying solder paste to the PCB, placing components, and then using heat to melt the solder, thereby forming electrical connections.

- Wave Soldering: This technique is primarily used for through-hole components. The PCB passes over a wave of molten solder, which coats the legs of the components and creates connections.

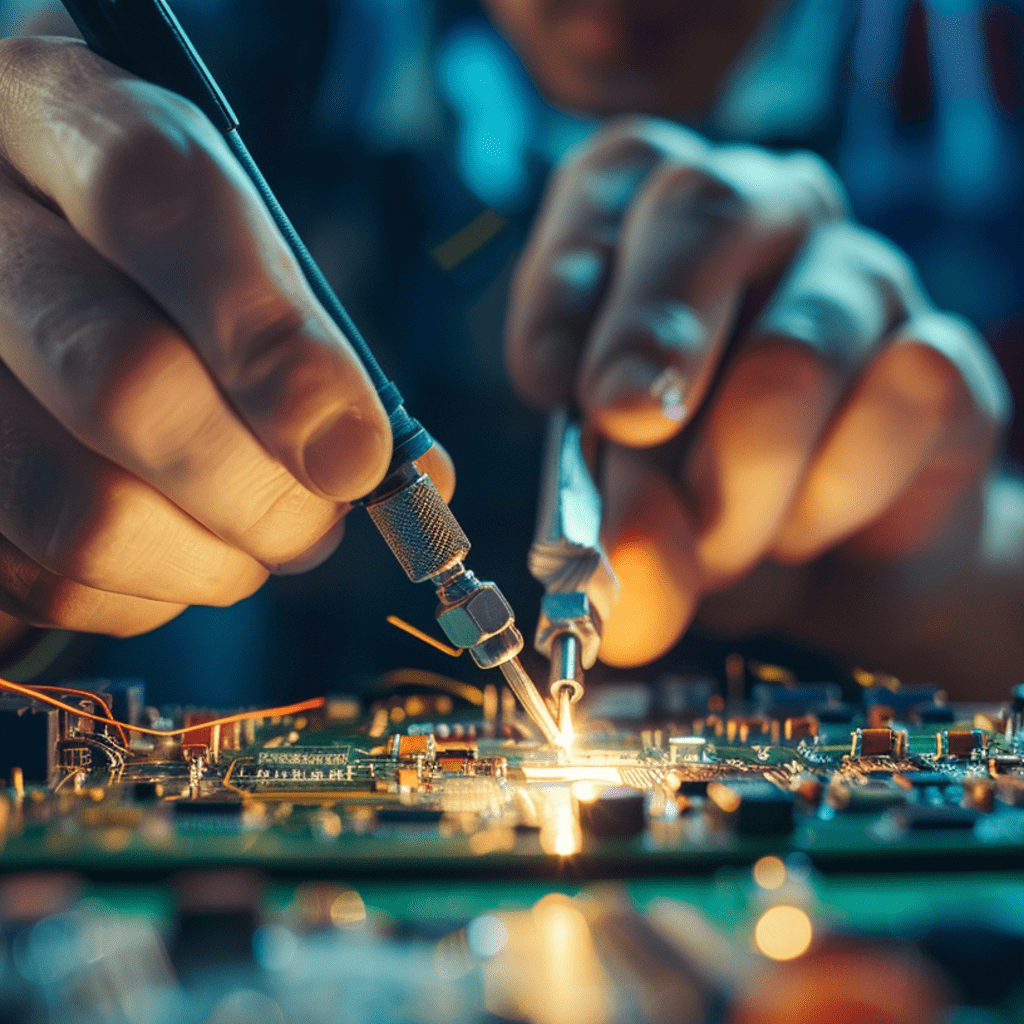

- Hand Soldering: In some cases, especially in low-volume production or for prototype boards, soldering is done manually using a soldering iron.

3. Inspection and Testing:

- Automated Optical Inspection (AOI): This method allows for the identification of defects such as misaligned components, insufficient solder, and other irregularities that may be missed during traditional inspection processes.

- X-ray inspection: It is used to examine the internal structures of electronic assemblies, particularly in printed circuit boards (PCBs), to ensure quality and reliability.

- Functional Testing: After assembly, the PCB must undergo functional testing to ensure that it operates as intended, which can involve simulations or running specific firmware.

PCB Assembly Process Overview

1. Design and Fabrication: Before assembly, a PCB must be designed and fabricated. The design is produced using CAD software, and the fabricated board is manufactured by etching conductive pathways onto a substrate.

2. Component Procurement: All necessary electronic components are sourced, either from suppliers or fabricated in-house.

3. Preparation: The PCB is cleaned, and solder paste is applied to pads where components will be placed (primarily for SMT).

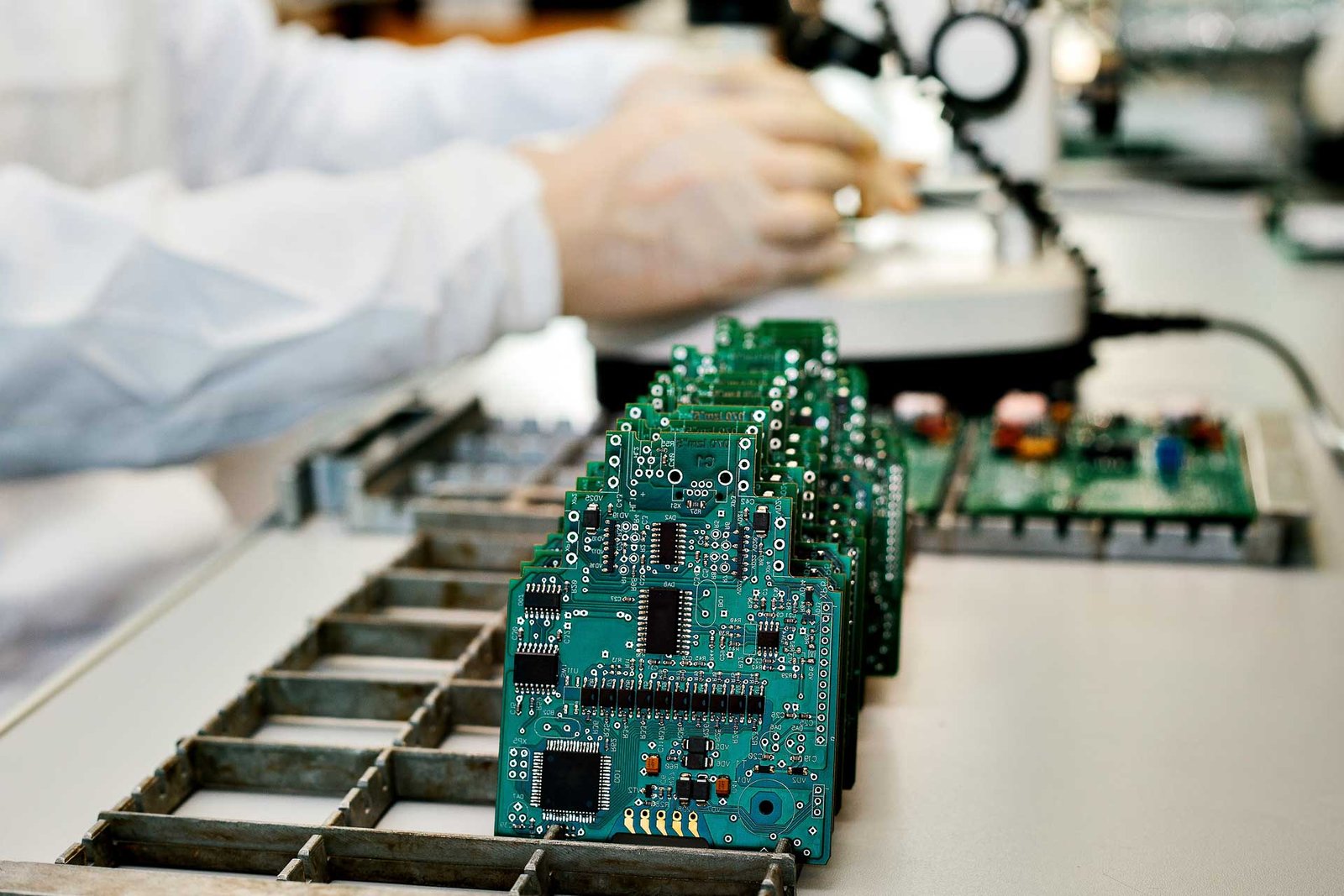

4. Placement: Components are precisely placed onto the PCB using pick-and-place machines for SMT or manually for through-hole components.

5. Soldering: The assembled board goes through the chosen soldering process (e.g., reflow or wave soldering) to create electrical connections.

6. Inspection: The assembled PCB is inspected for quality, accuracy, and defects.

7. Testing: Functional tests are conducted to ensure that the PCB performs as intended.

8. Packaging and Shipping: After passing inspection and testing, the assembled PCBs are packaged for delivery to customers or further integration into electronic devices.

Conclusion

In summary, PCB Assembly is a crucial step in the electronics manufacturing process that involves populating a printed circuit board with electronic components and ensuring electrical connectivity. Aoshuo Technolgy is a professional to offer turnkey electronic manufacturing services for you, we are willing to become your backup supplier by offer you our competitive price and high-quality products. Welcome to send your PCB Gerbers, BOM and pick & place file for trial quotation!

2025-01-18

2025-01-18