In the fast-paced world of healthcare, medical devices play a crucial role in improving patient outcomes and enhancing the quality of care. At the core of these devices is a technology that often goes unnoticed but is fundamentally important to their performance: printed circuit board (PCB) assembly. As a professional in the field, I’d like to delve into the significance of PCB assembly in medical devices and how it shapes the future of healthcare.

Understanding PCB Assembly

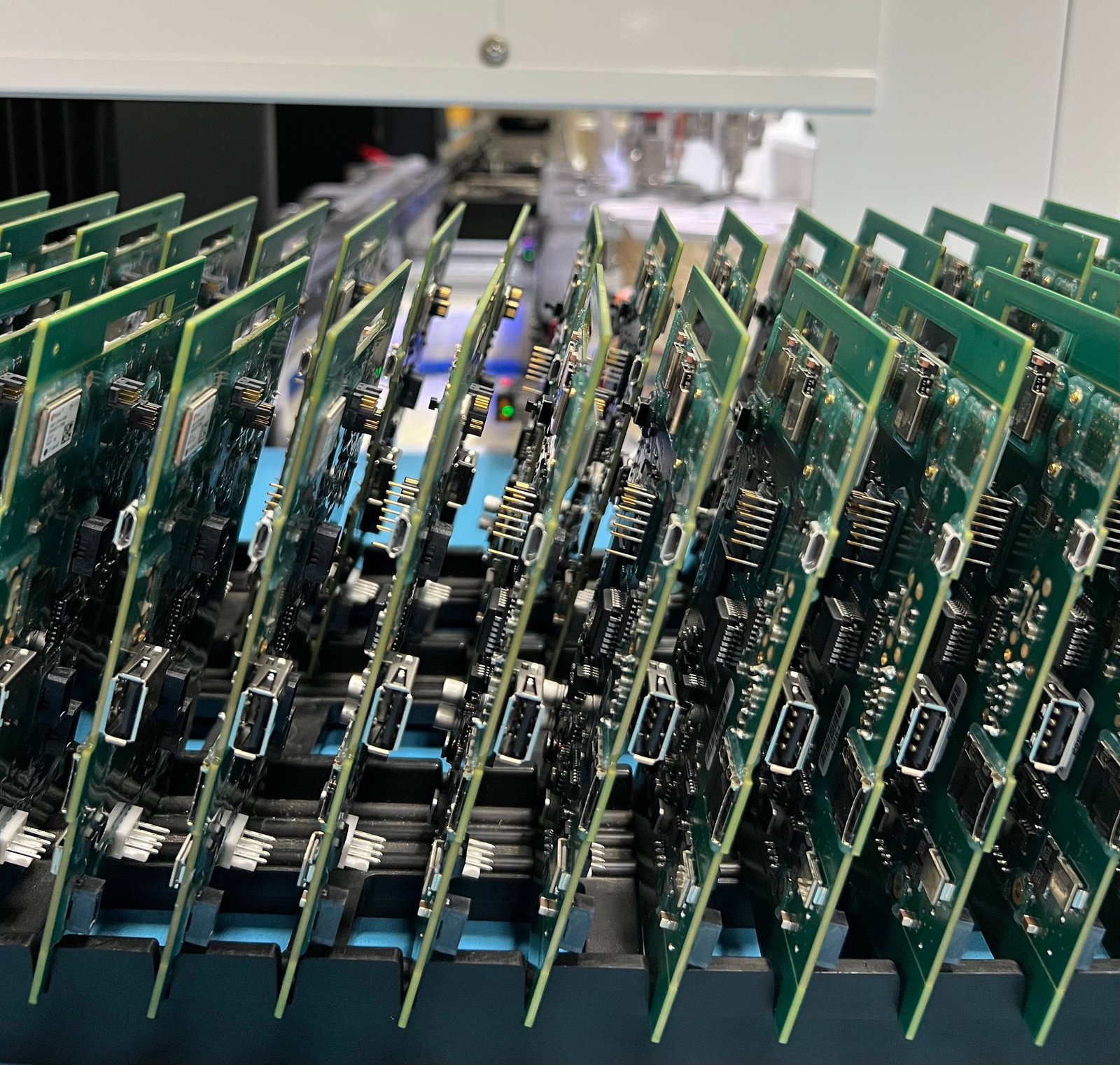

PCB assembly is the process of soldering electronic components onto a printed circuit board, allowing them to communicate and operate as a cohesive unit. This intimate relationship between components on a PCB is vital for the functionality of medical devices, ranging from simple diagnostic tools to complex surgical equipment.

Why PCB Assembly Matters in Medical Devices

1. Precision and Accuracy:

Medical devices require utmost precision. A single error in assembly can lead to device failure, potentially compromising patient safety. High-quality PCB assembly processes guarantee accurate placement and soldering of components, ensuring the reliability of devices such as ventilators, ECG machines, and infusion pumps.

2. Advanced Technology Integration:

Today’s medical devices often incorporate a variety of advanced technologies—from IoT connectivity that facilitates remote patient monitoring to integrated sensors that track health metrics in real-time. Robust PCB assembly is fundamental in the assembly process to ensure these components are seamlessly integrated, maximizing functionality and capabilities.

3. Regulatory Compliance:

The medical device industry is one of the most tightly regulated sectors globally. PCB assembly must meet numerous quality and safety standards, such as ISO 13485 and UL certification. Experienced manufacturers understand these regulations and ensure that every assembly process adheres strictly to compliance requirements, reducing risks for device manufacturers.

4. Reliability and Longevity:

Medical devices often operate in critical environments where reliability is non-negotiable. Quality PCB assembly techniques are essential to combat issues such as thermal management and mechanical stress. An expertly assembled PCB can dramatically increase the longevity of a medical device, leading to better patient care and reduced costs over time.

5. Cost Efficiency:

Efficient PCB assembly processes can reduce production times and lower manufacturing costs. This is especially important for medical device manufacturers who strive to keep prices competitive while ensuring high quality. By optimizing assembly techniques and using reliable sourcing strategies, companies can achieve cost-effective solutions for their device production.

The Future of PCB Assembly in Medical Devices

As technology continues to evolve, the future of PCB assembly in medical devices looks promising. Innovations such as automated assembly processes, advanced materials, and smart manufacturing practices are set to enhance the efficiency and reliability of PCB assembly. At Aoshuo Technology, we are committed to leveraging these advancements to deliver top-notch electronic manufacturing services tailored specifically for the medical sector.

Conclusion

The role of PCB assembly in the medical device industry is vital, underpinning the quality, reliability, and effectiveness of healthcare solutions. At Aoshuo Technology, we take pride in offering comprehensive electronic manufacturing services, including PCB fabrication, component sourcing, PCB assembly, programming, and functional testing. Together, let’s continue to drive innovation in medical devices and improve patient outcomes through high-quality PCB assembly.

2025-01-06

2025-01-06