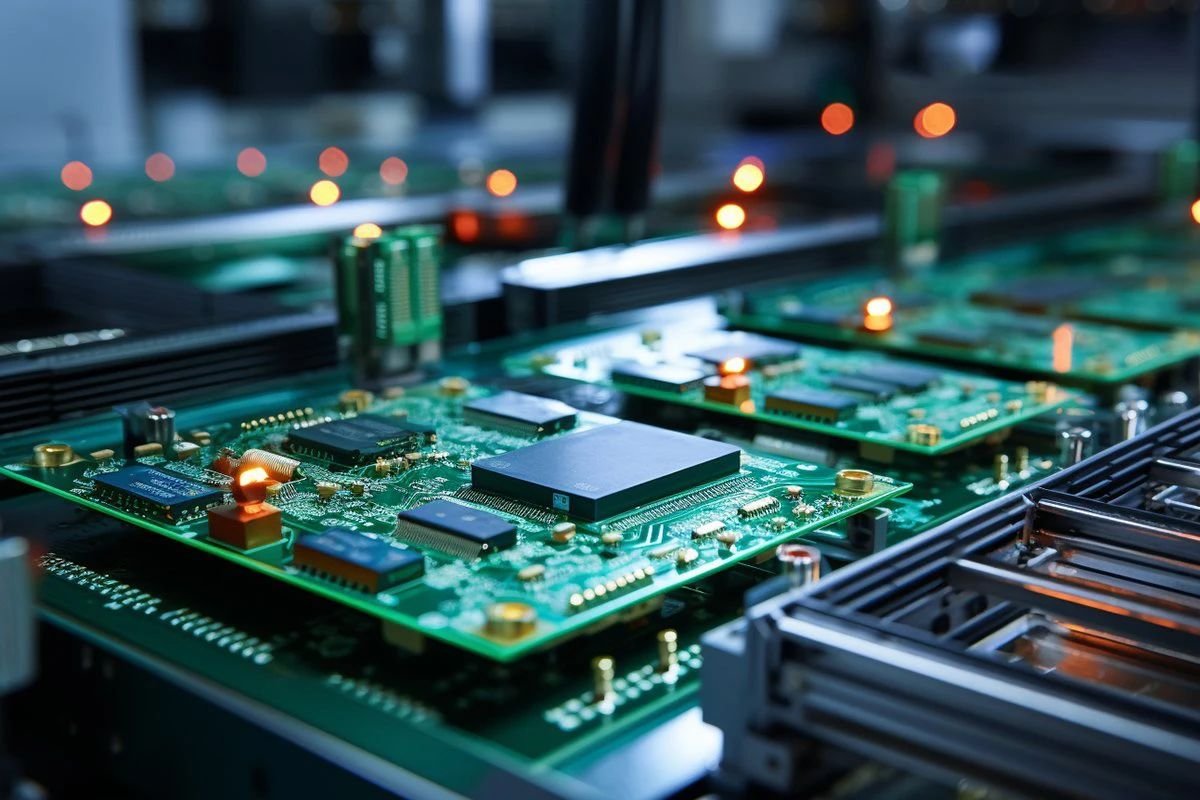

PCB base material refers to the substrate or foundation layer used in the construction of printed circuit boards (PCBs). This material provides mechanical support, insulation, and electrical conductivity for the various electronic components mounted on the PCB. The choice of base material is critical as it affects the performance, reliability, and overall characteristics of the PCB.

Common Types of PCB Base Materials:

1. FR-4:

- The most commonly used material for PCB.

- Made from woven fiberglass and epoxy resin.

- Good electrical insulation properties, thermal stability, and strength.

2. CEM-1 and CEM-3:

- CEM-1: A composite material with a paper base and a single layer of copper.

- CEM-3: Similar to FR-4 but has a lower cost and is often used for single-sided boards.

3. Polyimide:

- Known for its excellent thermal and chemical resistance.

- Typically used in flexible or high-temperature applications.

4. Roger's Materials:

- A brand of high-frequency laminates designed for RF and microwave applications.

- Offers stable dielectric properties over a wide frequency range.

5. Alumina Ceramics:

- Used in special applications requiring high thermal conductivity and electrical insulation.

- Common in high-frequency and high-power electronics.

6. Metal Core PCB:

- These include a metal layer (commonly aluminum) for better thermal management.

- Often used in LED applications and power electronics.

Key Properties Considered in PCB Base Materials:

- Dielectric Constant (Dk): A measure of the material's ability to store electrical energy in an electric field.

- Dissipation Factor (Df): Relates to the material's loss of energy as heat when subjected to an alternating electric field.

- Thermal Conductivity: The ability of the material to conduct heat, extremely important for high-power applications.

- Mechanical Strength: The ability to withstand physical stresses without deforming or breaking.

- Moisture Absorption: Determines the reliability and longevity of the PCB under varying environmental conditions.

Conclusion:

Selecting the right base material is critical for achieving the desired functionality and performance of electronic devices, particularly as operating frequencies and thermal requirements increase in modern electronics. With many years experience in PCB manufacturing, Aoshuo is professional to produce all kind of PCB boards for you to meet your diverse specification and design.

2025-01-18

2025-01-18