In the PCB industry, balancing manufacturing costs and product quality is a huge challenge. You need to identify the expenses involved in each stage of PCB development. There are multiple factors affecting the quality of PCB during fabrication and assembly. Knowing the PCB assembly cost breakdown can assist the designer in choosing the right components for the PCB design. Along with the pricing of the components, features like the board size, PCB material, number of layers, type of PCB assembly method, etc impact the overall PCB fabrication and assembly cost. Further services like testing, packaging, and shipment will add to the total PCB production cost. Collaborating with an experienced contract manufacturer (CM) will benefit in reducing costs and building quality PCB products.

There are some assembly challenges commonly observed during PCB manufacturing. They can be a shortage of components, non-standard PCB dimensions, wrong positioning of the inspection equipment in the assembly line, and many more. In turnkey PCB assembly, your CM will have an excellent network for component sourcing. This helps procure genuine parts at lower prices. It is recommended to add alternate parts to the Bill of Materials (BoM), especially for components that are specific to your board functionality. Choosing a standard PCB size may not be viable in many cases. But both large and small boards can add extra assembly costs. After PCB assembly, it is crucial to inspect the board for any visible placement and soldering faults. Your CM should have the latest assembly setup with optical inspection machines suitably placed in the assembly line. This is essential to increase line efficiency.

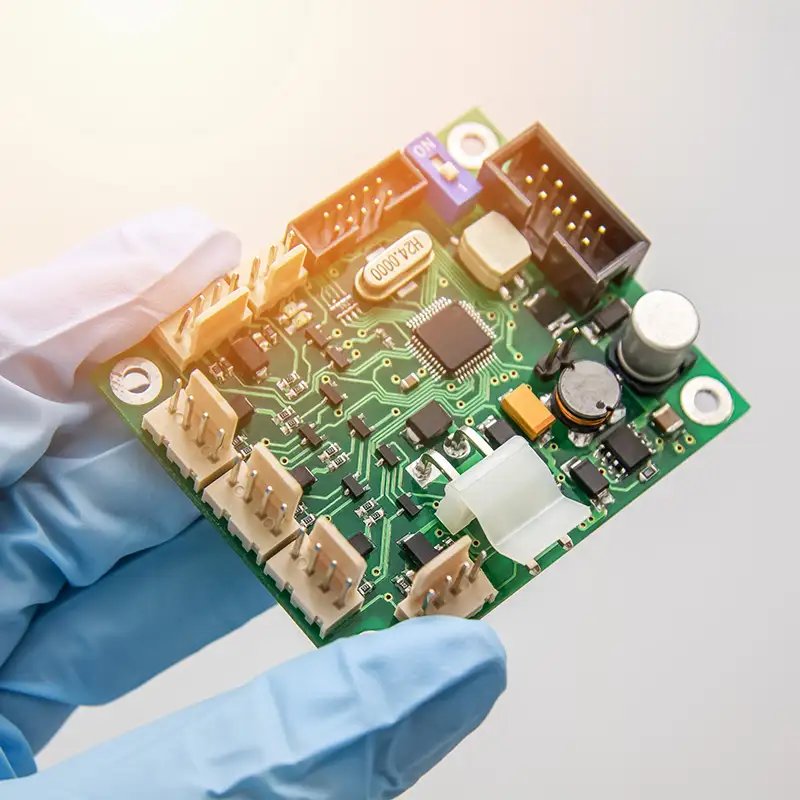

PCB Assembly Cost Breakdown

If we break down the various components of a PCB assembly cost, it will be mainly the following four items:

1. Bare board cost

Usually, PCB fabrication and assembly are done together. The cost of bare board manufacturing depends on the material selected, the number of layers, and the board size. You must share the Gerber file and other important PCB design files with your CM for the PCB fabrication.

2. BoM cost

This is the expensive part of a PCB assembly. The bill of materials provides the list of all components and sub-assemblies required for the product assembly. You may have to keep margins for material wastage during the PCB assembly.

3. PCB Assembly cost

The type of assembly technique used determines the labor and engineering requirements of the PCB assembly. Mounting the components on the bare board is a critical process. Surface Mount Technology (SMT) method is commonly used and is cost-effective.

4. Board Testing cost

The assembled PCB must undergo visual inspection and functionality testing. It is recommended to include PCB testing and debug support from your CM. This will save time and assist your CM in improving the assembly line for the next production batches.

It is beneficial to know the various aspects that influence PCB assembly pricing. This will guide you in optimizing the overall PCB production cost.

2024-10-08

2024-10-08